Ask Captain Lamp

Here are some frequently asked questions.

Don’t see your specific question, please e-mail webmaster@xslighting.com, Captain Lamp will be glad to respond.

What is the difference between standard and long life lamps?

For most theatrical lamps, the standard lamp life is approximately 300 hours. Many of these lamps are available in Long Life or eXtended life versions which should last approximately 1500 hours.

To achieve this dramatically longer lifespan, the lamps are designed to operate at a lower CCT (Correlated Color Temperature) and also at a 25% reduction in output.

If the luminaire is challenging to re-lamp, the long life lamp may be your solution, however, if you need the output, stick with the standard life lamp.

What is the difference between 120 volt lamps and 115 volt lamps?

Power from a wall receptacle is generally targeted to be 120 VAC (Volts AC or Alternating Current). This can vary depending on your particular location on the electrical grid. If you are plugging an incandescent lamp straight into a wall receptacle, it is best to use a 120v lamp.

Due to certain inefficiencies of dimmers, particularly theatrical dimmers, even if your supply voltage is 120v, by the time it passes through the dimmer, the choke, and approximately 100′ of wire, the voltage which arrives at the luminaire has been reduced by a few percent.

To achieve full output from your lamp, full voltage must be provided, and since a 120v lamp will likely never receive a full 120v via a dimmer, 115v lamps were designed to achieve full output on a dimmed circuit.

How can I extend my lamp life, without extended life lamps?

Dimming an incandescent lamp by as little a 5%, output which most humans cannot detect, can effectively double the lamp life, dimming 10% can almost triple lamp life.

Conversely, plugging a 115v lamp into a 120v receptacle will be much brighter, but will significantly reduce lamp life.

My lamp is bad, but the filament looks good; why?

If you remove a lamp from a fixture, but the filament is still fully intact, check for electrical continuity across the lamp pins before pitching the lamp and installing a new one. If no continuity is detected, this may be an indication of a bad lamp socket. Burnt lamp pins are also an indication that your socket needs to be replaced.

Incandescent lamp filaments produce a LOT of heat energy, however, they are designed to withstand this heat. The lamp base is NOT supposed to create heat, however, a bad socket will create resistance, and electrical resistance creates heat, and the lamp is not designed to dissipate heat coming from both ends.

Check your socket, if either of the socket connections look burnt, corroded, or indicate any other cause for poor electrical contact, you should replace that socket prior to installing a new lamp.

Installing a good lamp in a bad socket is a death knell for the new lamp.

Into the weeds – what happened to the lamp…

In the lamp manufacturing process, air is evacuated from the lamp envelope or ‘bulb’, and replaced with a special gas mixture which promoted better filament life. This gas mixture is sealed inside at the ‘pinch’, the flattened portion of the lamp between the filament and the lamp pins. Since glass and most metals expand at a different rate, the lead wires connected to the filament and the pins at the base are soldered to two special pieces of material called Molybdenum foil, at the point of the pinch. Molybdenum has a similar expansion coefficient to the quartz glass envelope or bulb, which allows it to form a tight seal with the glass. Should just one of these four points become unsoldered due to the extra resistance heat at the socket, game over, the lamp is toast.

Why do the lights buzz when dimmed?

Dimmers utilize SCRs (Silicon Controlled Rectifiers) to essentially chop up the AC (Alternating Current) sine wave.

The SCR turns off at the zero crossing point, the point where the sine wave alternates from above zero to below zero. In 60 Hz (Hertz) or 60 cycle power, this occurs 120 time per second. Since the SCR can only pass current in one direction, so a second SCR is wired in reverse to accommodate the other half of the wave.

For a 50% dim, the SCR shuts off at the zero crossing point, and turns back on halfway through the wave where it spikes on and ramps back to zero, this is repeated for the other half of the wave with the second SCR, then back to the first, and repeat.

The issue is that the spike ‘on’ is a significant inrush of current, which causes the lamp filament to twitch, over and over again, 120 times a second. This twitching is smoothed out by the choke, but it is an imperfect process, especially if multiple lamps are ‘singing’ at the same frequency.

House light dimmers typically utilize a larger choke, with a higher rise time, which helps to mitigate the buzz, but this also increases time to dim up and dim down, which is less appropriate for your theatrical luminaires.

The buzz is exacerbated by multiple filaments ‘singing’ at the same frequency, which creates a harmonic, so dimming at slightly different percentages could help alleviate the volume, but won’t make it go away.

What is the best lamp for my luminaire?

The best lamp for your fixture, or luminaire, is the one which achieves the desired output results with the fewest input Watts.

Most of the energy which is consumed by your luminaire is turned into heat, 96.5% in fact. Only 3.5% of the Wattage consumed by an incandescent lamp produces light.

One of the most common luminaires in the theatrical lighting world is the ETC Source 4 ERS (Elliptical Reflector Spotlight), also known as a S4 Ellipsoidal. This fixture was designed around the HPL575/115 lamp. Even though the S4 had superior output to most ellipsoidals of the day utilizing 1000 Watt lamps, many people requested a higher Wattage lamp. This the HPL750 was introduced.

Even though the HPL750 produces significantly more initial lumens via a longer set of filaments, the reflector of the S4 ERS is designed to capture the more compact filament design of the HPL575. In a HPL575 to HPL750 shootout, most cannot discern a difference in output. Unless you want to waste energy, swap your HPL750 for HPL575, and carefully bench focus the luminaires.

The parabolic reflector of ETC PARs, PARNels and Fresnels do utilize the additional output of the HPL750 lamp.

As for non ETC ellipsoidal fixtures, there is a plethora of outstanding replacement lamps which often outshine the original lamp they are replacing. The key is to find the best alternative lamp for your fixture.

If you are still using 1000 Watt FEL lamps, consider switching to the FLK, originally introduced as the HX-600. This lamp has the same coil filament as the FEL, 750 Watt EHG and 500 Watt EHD, but as it is designed to operate at 115v, produces full output from a dimmed circuit. (See What is the difference between 120 volt lamps and 115 volt lamps). Changing to a more compact filament will require bench focus of your luminaire, but in the end will be well worth it.

If your luminaire was designed around a coil filament, it likely has a smooth, or smoothish reflector. If your luminaire has a faceted reflector, similar to the S4 ERS, it was designed around a multi-filament lamp, and will be most efficient with that style lamp.

Can I energize Moving Lights and LED luminaires from a dimmer circuit?

The short answer is: in a pinch maybe, but you really shouldn’t use a dimmer for LEDs or moving lights.

Dimmers chop up the typically smooth AC sine wave, and even a dimmer parked at full, creates tiny anomalies in the flow of current.

Best practice is to never energize any device containing electronic circuitry with a dimmed circuit. It may work for awhile, but there is a likelihood that eventually something is going to fail.

If you have an ETC Sensor Rack, you can easily swap a D20 dual Dimmer Module for an R20 dual Relay Module.

If your dimming system manufacturer does not offer a relay module option, there are inline solutions such as the ETC ColorSource DMX Relay. This device will automatically energize up to 15 amps of luminaires when DMX is present, and will de-energize them about 30 seconds after the DMX signal is no longer present.

Do I have to terminate DMX?

DMX is a lighting control protocol similar to the serial data computer language RS-485, and should always be terminated, especially with long runs.

DMX is a series of commands which are constantly refreshed, even if the new data is the same. When the DMX signal hits the last device in a string of luminaires, there is the potential for the signal to reflect back down the DMX cable, and if the old data is inconsistent with the new data, you will have undesirable results from the conflicting commands.

DMX termination is easy, it is a 120 ohm resistor between Data- (Pin 2) and Data+ (Pin 3) of the XLR connector.

It is always good practice, but especially if you are having issues, terminate your DMX.

Can I 'Y' the DMX signal?

NO NEVER.

Creating a ‘Y’ with the DMX signal degrades it, and can cause fixtures anywhere in the chain to behave erratically.

The ONLY way to properly send DMX in two or more directions is an active splitter, more succinctly an Opto-Splitter. The DMX signal emanating from each output of an Opto-Splitter is a brand-new, clean signal, as if the signal came out of the console.

The other benefit of an Opto-Splitter is that each path is isolated, so if something corrupts the signal on one of the splitter outputs, it cannot effect the other outputs.

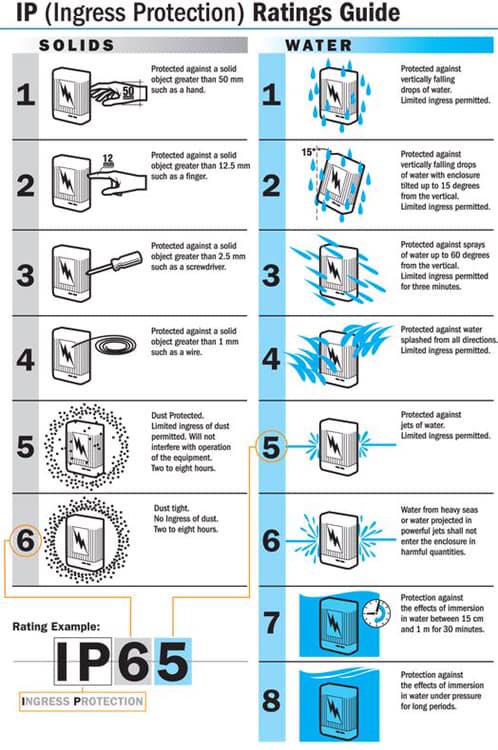

What is an IP Rating

IP stands for Ingress Protection, ingress protection may also be referred to as an IP rating or IP code.

The IP code is composed of two numbers:

The first number refers to the protection against solid objects and is rated on a scale from 0 (no protection) to 6 (no ingress of dust).

The second number rates the enclosure’s protection against liquids and uses a scale from 0 (no protection) to 9 (high-pressure hot water from different angles).